- Conveyors

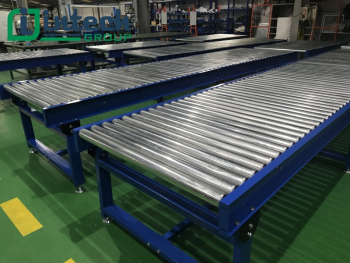

- Conveyor belt

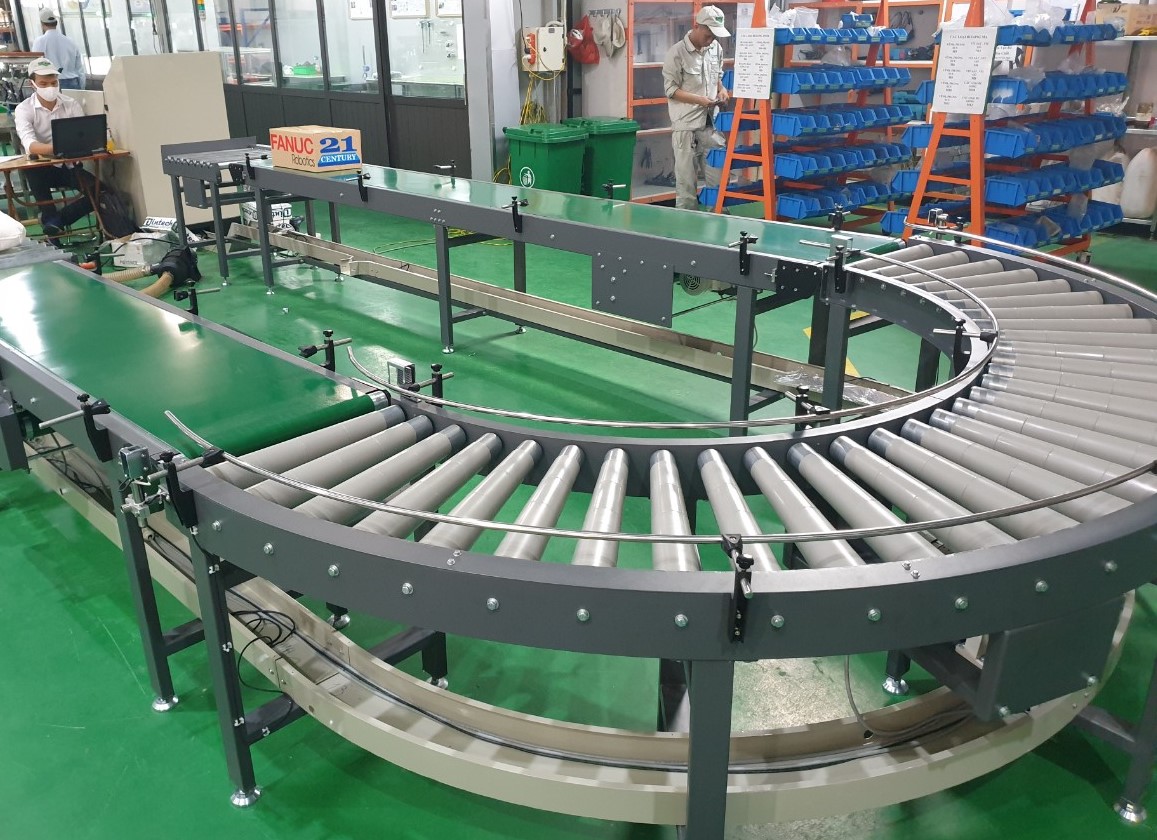

- Conveyor Systems

- Assembly Line

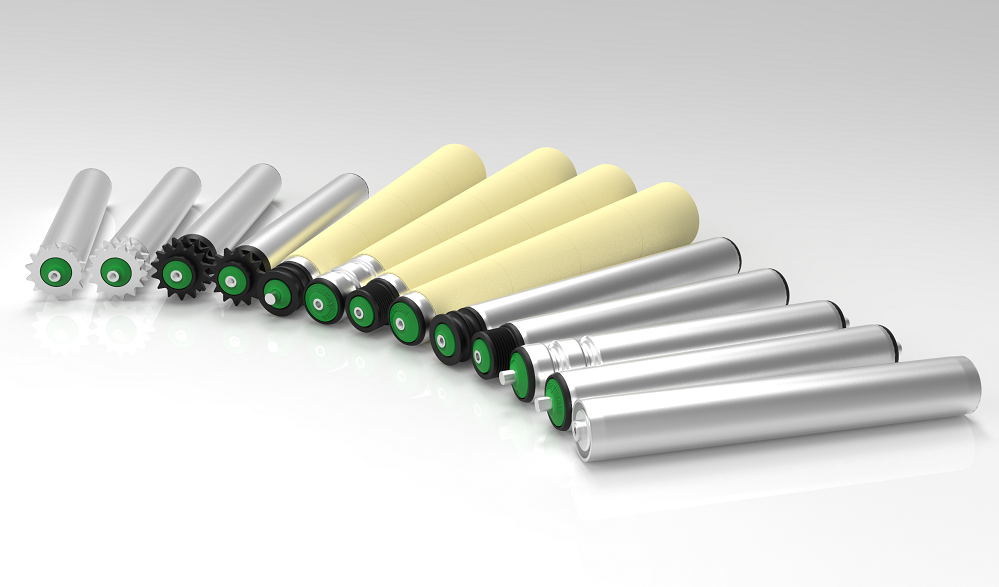

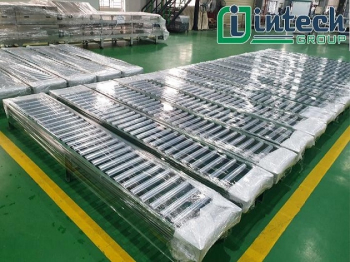

- Rollers, Roller System

- Carton packing machine

- Pallet wrapping machine

- Precision mechanical processing

- Working table, assembly table

-

Ha Noi Factory

Add: Lot 5 + 6, Lai Xa Industrial Park, Hoai Duc District, Hanoi.

Tel: 0966.966.032 - 0986.448.456

Email: info@intech-group.vn

Hotline: 0986 448 456 - 0966 966 302 - 0966 966 301 -

Da Nang Factory

Add: 215 Phan Dang Luu, Cam Le District, Da Nang City

Tel: 0983.11.33.87

Email: info.dn@intech-group.vn

Hotline: (+84)966 966 359 -

Ho Chi Minh City Factory

Add: Lot D6, Street 3, Binh Chieu Industrial Park, Thu Duc District, Ho Chi Minh City

Tel: 0967.505.001 - 0981 51 8001

Email: info.hcm@intech-group.vn

Hotline: 0981 51 8001 - 0967 50 5001

INTECH ROLLER - International Standard Industrial Roller

Intech Group - Specialist in manufacturing rollers according to international standards with high precision and durability, various types of conveyor rollers applied in "conveyor systems" using industrial rollers.

Roller (roller) is used in many modern industrial production branches. Rollers are processed and manufactured according to international standards with high precision, ensuring durability and safety when used. Roller structure includes ball bearing, roller housing, roller shaft and some attached components.

Why do partners choose Intech Group's Roller?

- All of our product lines are manufactured according to ISO 9001: 2015 quality standards through years of research and development in accordance with international standards, products are thoroughly tested from processing to assembly and test

- Large-scale manufacturing factory with headquarters in Hanoi and Ho Chi Minh City

- Modern machinery and technology

- Stable and high quality input materials from major partners

- Professional and modern production process with complete testing equipment and professional service.

- Skilled and well-trained labor

- Strict quality control process right from all stages of production

- Intech Group handles Customer's requests very quickly, accurately and professionally.

- Ensure accurate progress right from sample orders.

- Intech Group has drastically improved and changed the quality of products and services to meet the requirements of customers.

| |

Intech Group processes and manufactures industrial rollers with the following criteria:

- International standard roller sizes: Ø25, Ø32, Ø38, Ø42, Ø49, Ø60, Ø76, Ø114,...

- Machining of conveyor rollers will depend on the size and speed of the conveyor;

- Roller shaft must have sufficient rigidity;

- Roller bearings are of clear origin;

- Rollers must be mounted so that both sides are concentric;

- When manufacturing rollers, it is necessary to ensure that the running rollers do not shake and rotate smoothly;

- Roller surface must be shiny treatment;

- Materials for making rollers include: steel, stainless steel, plastic, rubber....;

- Intech roller price list based on size and materials used;

Intech Group manufactures all kinds of international standard industrial rollers

Intech is a manufacturer of industrial rollers with the No. 1 quality standard in Vietnam. Intech Group roller products are processed and manufactured according to international standards, and all rollers are strictly inspected before being shipped. Types of rollers used in making conveyors, conveyor belts help convey large and small materials easily. In particular, we pay great attention to the concentricity and the ability of the roller to keep grease because these are the two factors that determine the quality and life of the roller, so customers can be completely assured when using it. use.

Quý khách hàng có thể đặt hàng xe lu của chúng tôi để được cam kết về chất lượng và giá cả tốt nhất. Báo giá con lăn băng tải Intech nhanh nhất, chính xác nhất để khách hàng lựa chọn. Để khẳng định chất lượng con lăn của mình, chúng tôi áp dụng chế độ bảo hành thay thế toàn bộ trong thời gian bảo hành.

Traditional roller products of Intech Group:

-

Special Roller Conveyor

-

Curved Roller Conveyor

-

IT3 Roller Conveyor

-

Electric Roller

-

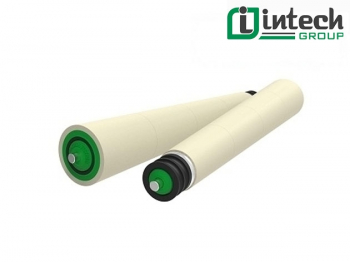

Tapered roller

-

Belt Driven Roller

-

Chain drive roller

-

Free drive roller

-

Seamless galvanized steel rollers

-

Rubber coated roller

-

PU plastic roller

-

Plastic Roller

-

Seamless double roller

-

Seamless steel roller

-

Stainless Steel Roller Seamless

-

Flexible stacking rollers

-

Stainless steel conveyor roller

-

Mini industrial roller system

Frequently asked questions