- Conveyors

- Conveyor belt

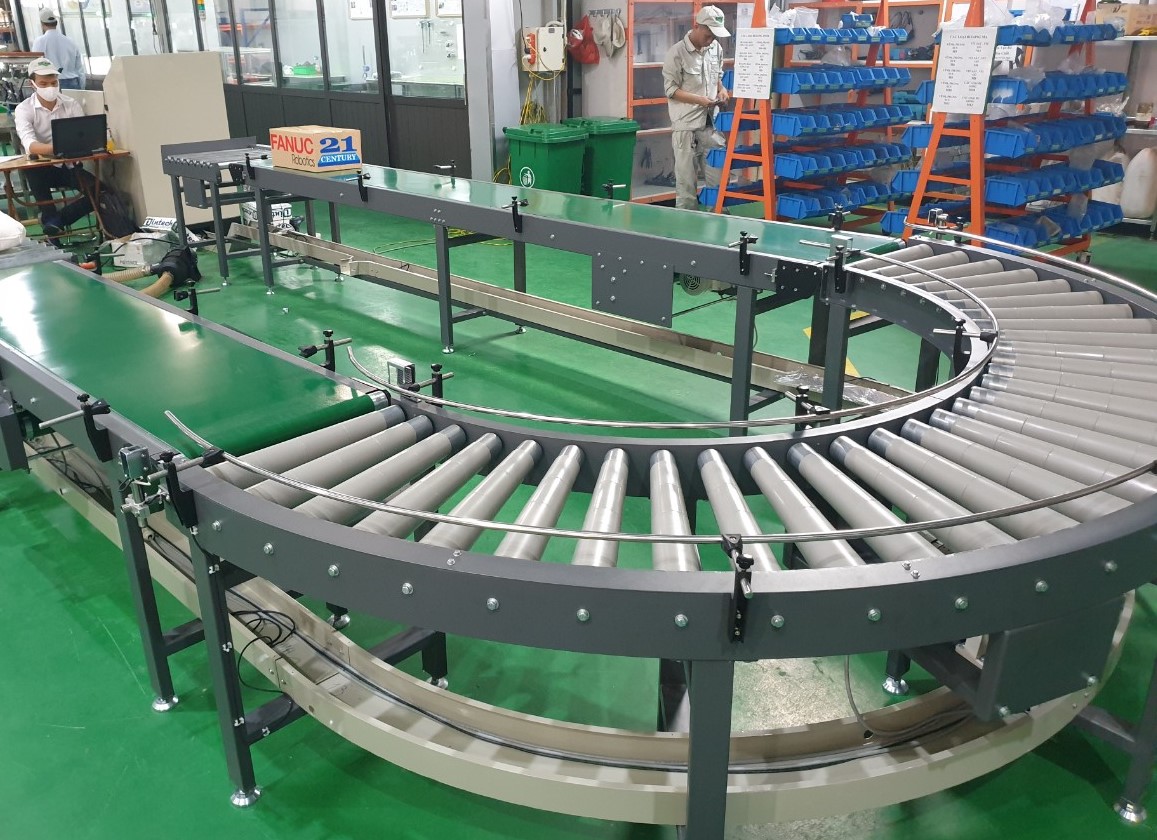

- Conveyor Systems

- Assembly Line

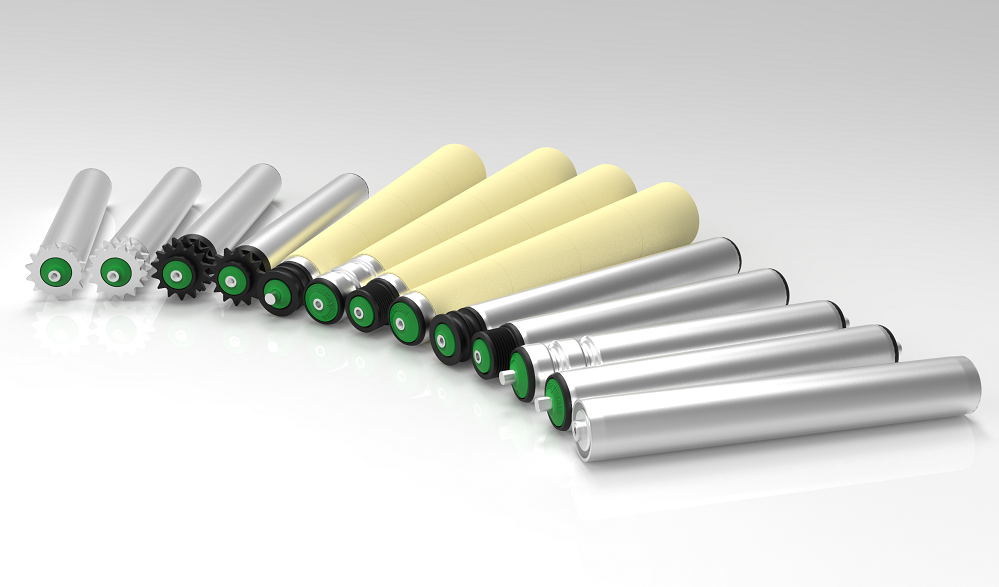

- Rollers, Roller System

- Carton packing machine

- Pallet wrapping machine

- Precision mechanical processing

- Working table, assembly table

-

Ha Noi Factory

Add: Lot 5 + 6, Lai Xa Industrial Park, Hoai Duc District, Hanoi.

Tel: 0966.966.032 - 0986.448.456

Email: info@intech-group.vn

Hotline: 0986 448 456 - 0966 966 302 - 0966 966 301 -

Da Nang Factory

Add: 215 Phan Dang Luu, Cam Le District, Da Nang City

Tel: 0983.11.33.87

Email: info.dn@intech-group.vn

Hotline: (+84)966 966 359 -

Ho Chi Minh City Factory

Add: Lot D6, Street 3, Binh Chieu Industrial Park, Thu Duc District, Ho Chi Minh City

Tel: 0967.505.001 - 0981 51 8001

Email: info.hcm@intech-group.vn

Hotline: 0981 51 8001 - 0967 50 5001

PRODUCTS ASSEMBLY LINE SYSTEMS

Intech Group's product assembly line has become the choice of many businesses, Intech Group's assembly line systems are designed according to the requirements of businesses to meet the maximum specific production needs of customers. Every enterprise, factory.

What is an assembly line?

An assembly line is a manufacturing process that divides labor by breaking down the production of a product into steps that are completed in a predefined sequence. The method most commonly used in the mass production of products.

Classification of assembly lines

Assembly lines can be used for different purposes. They are often tailored to the products being manufactured. But the types of assembly lines are generally divided into the following categories:

1 - Automated line: A line using completely machines or with very little human impact.

2 - Classic line: A line that combines people and machines to create a product, such as an automobile or an airplane.

3 - Discontinuous line: This type of assembly line produces similar but not identical products.

4 - Flexibility: Assembly lines are geared toward producing a particular product in large quantities, which can make it difficult for a company to be flexible when it wants to shift production to different product categories. .

Advantages of the assembly line when manufacturing products

Assembly line manufacturing is a popular production method that offers some huge benefits to startups as well as large enterprises around the world.

1 - Labor and capital specialization:

2 - Homogeneous product:

3 - Initial costs:

4 - Flexibility:

Why should you choose Intech's product assembly line?

- Intech is proud to be the leader in the production and installation of automatic and semi-automatic assembly lines to serve domestic and foreign enterprises and factories.

- We constantly improve our capacity, improve technology and quality to meet the requirements of industrialization and modernization.

- Our main partners are the production and assembly factories of Korea and Japan operating in Vietnam and many factories following the industrialization model.

- Intech always supports and brings customers the most comprehensive and effective solutions.

Product assembly lines of Intech Group:

-

Electronic circuit board assembly line

-

Electronic Assembly Line

-

Industrial Assembly Line

-

Single Assembly Line

-

Double Assembly Line

-

Electronic Components Assembly Line